New Technology for Optimal Engine Maintenance

Automakers recommend that vehicles have a maintenance check at least once a year but by the time a car is a few years old, its engine may have issues that require major expense to fix, and much of the problem lies in late diagnostics. New innovations such as A.I., robotics, and advanced visualization machinery are enabling mechanics and vehicle owners alike to spot problems at the very outset. Doing so enables them to nip problems in the bud before they become major bugbears and/or budget breakers. How are new technologies changing the engine maintenance game and which companies are heading the race?

Self-Diagnosing Cars

Imagine a vehicle that had the ability to self-diagnose any issues encountered under its bonnet, automatically pre-ordering replacement parts if required. Tesla has made this possible, with all newer makes keeping tabs on specific components so that parts can be ordered ahead of vehicle owners’ next maintenance visit. “It’s like skipping the doctor and going right to the pharmacy,” says Tesla management, highlighting the benefits of early diagnoses.

Sound Says it All

Skoda is all over the news of late and it’s all owing to its new ‘sound analyzer’ smartphone app. The app uses AI to speedily identify the need for servicing. It works by recording noises made by the car, comparing it with stored sounds. When discrepancies arise, the app relies on an algorithm to determine the cause, helping to make maintenance more efficient. The app is part of the company’s push to digitalize processes and to consistently rely on artificial intelligence for optimal customization.

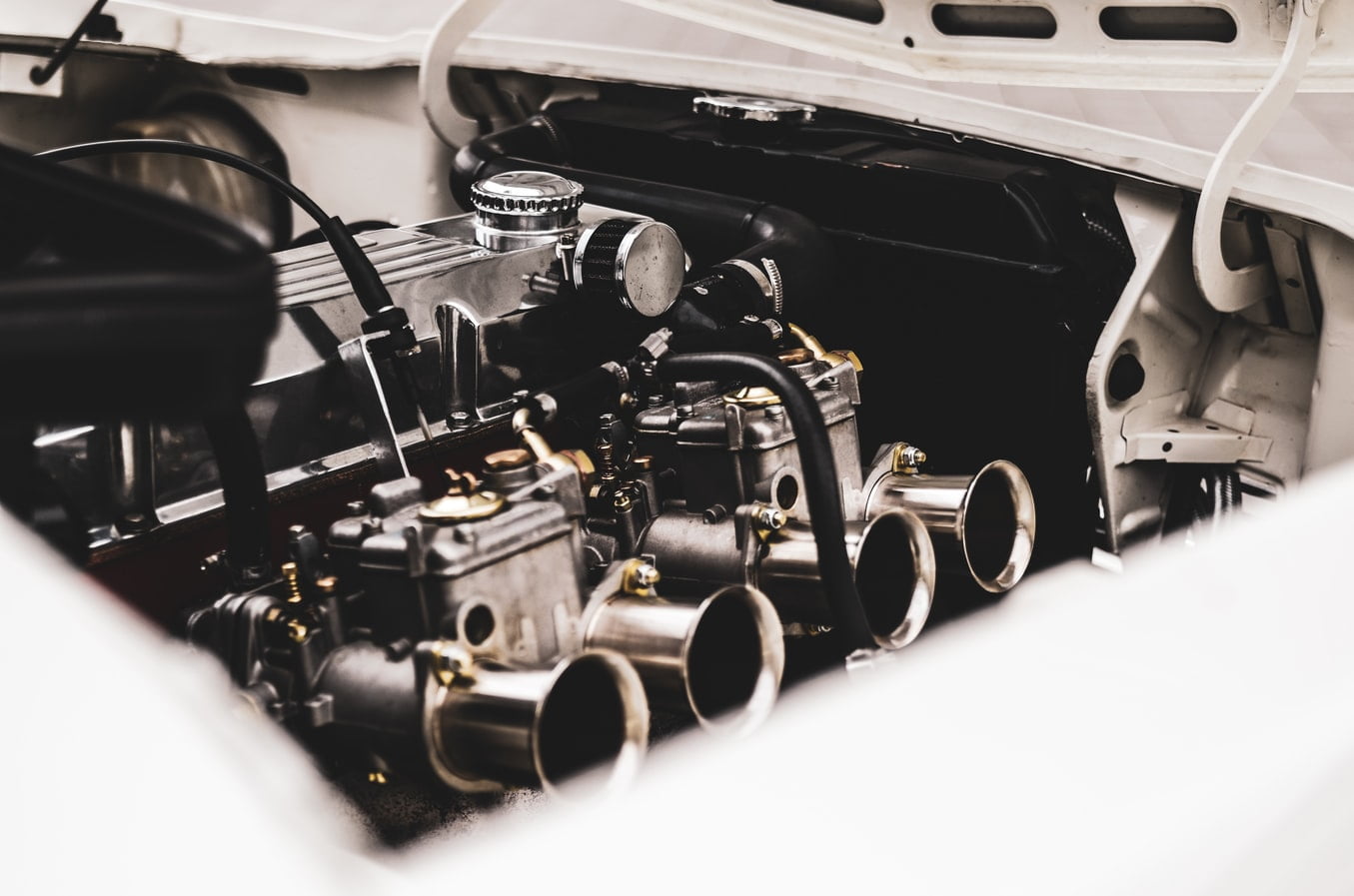

Articulating Borescopes

Spi borescopes enable mechanics to inspect the inner workings of machinery without having to take it apart. Video borescopes present images on a screen, offering features such as four-way, 360º articulation – which allows the camera to capture all angles of machinery. Through the use of advanced connectivity, images captured are then presented on screens as large as 60 inches, enabling mechanics to get a crystal clear vision of any problems present.

Robotic Maintenance

Rolls-Royce has been aiming to revolutionize the future of engine maintenance through robotics for the past few years. The luxury marque teamed up with academics from Harvard University and the University of Nottingham, demonstrating a wide range of robotic technologies – including snake robots that enter an engine, endoscope-style, and miniature robots that crawl inside engines. These mini robots, called SWARM, measure around 10mm in diameter. Each carries a small camera that provides live video to the mechanic, enabling the latter to fully inspect an engine without disassembling it first.

It’s an exciting time for car and airplane engine maintenance, with technologies ranging from sound analyzing apps to tiny robots making inspection easier and quicker. These technologies can do everything from ordering needed parts to identifying tiny damage in engines that may be hard to spot with less sophisticated visual machinery. Maintenance is now speedier and more cost-effective than it has been in the past but above all it saves on time, since engines no longer need to be taken apart to discover their inner workings.