Drive Belt Tensioners: A Key to Vehicle Performance

Know the ins and outs of your engine, or how power is transferred to different engine and vehicle parts? When it comes to belts, the basic divide is between timing and drive belts. The first is to connect the cam and crankshaft to ensure valves open and close in sync with the pistons, basically ensuring correct “timing” and engine efficiency. The second drives vital parts such as the alternator, water pump and air conditioning.

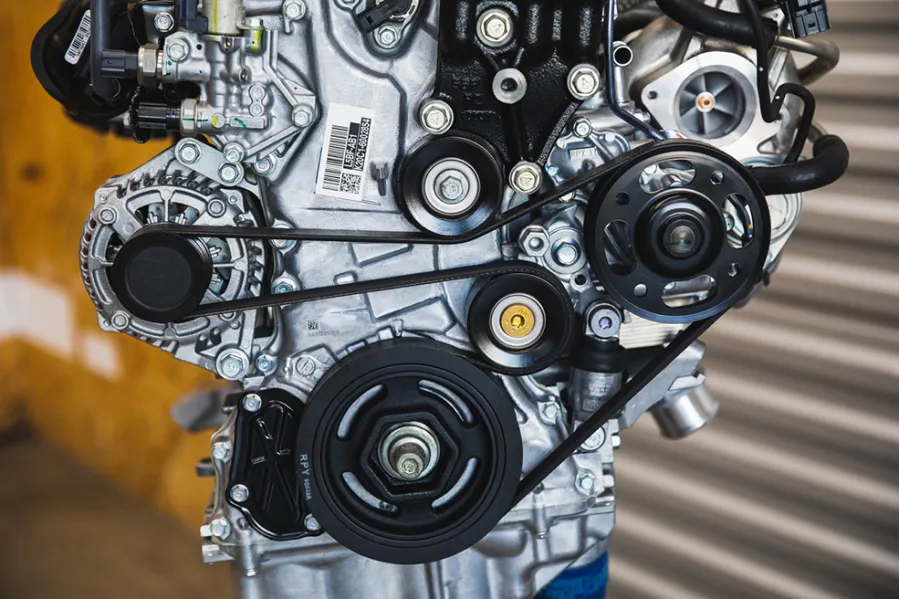

Pop up the hood, and you’ll likely see a drive (or serpentine) belt that slithers through the engine bay and is connected to pulleys attached to the front of the crankshaft. To provide power to several parts and systems, a drive belt is quite long, so it also requires a system of pulleys or a drive belt tensioner assembly to keep it running its course. This provides the right tension or pressure on the belt, prevents it from slipping, and deals with alignment issues.

How Belt Tensioners Work

Whichever name they go by, drive belts, fan, serpentine or auxiliary belts work by transmitting the rotational force from the crankshaft to the parts they drive. As the engine speeds and the load from connected parts like the air conditioner compressor changes, belts can stretch and lose tension. For example, a compressor valve is to balance the pressure of the fluids moving through the system by controlling the angle of the swash plate. This keeps the evaporator at a constant temperature slightly above freezing to maximize the auto air conditioning system operation.

This is where tensioner pulleys come into the picture. They’re bolted onto the front of the engine, with the flat side of the belt resting on the pulley. Pulleys rotate with the belt as it moves in engine bay and ensure the belt is tight enough to power auxiliary systems.

Main Types

If you’re suspecting signs that the belt or tensioner pulleys aren’t working as they should, then you’ll need to know which type to get as an operational replacement. Most serpentine belts now are of the V-belt type and can be sitting on either a spring-loaded or hydraulic tensioner pulley.

The first consists of a spring and an oscillating swing arm to cut out slack. This type of drive belt tensioner assembly can be either mechanical, with tension adjusted manually (and a feature in older cars), or automatic, as we usually see today, with the pulley changing the tension in the belt as engine speeds and loads change. Both types are more common in smaller displacement, 4-cylinder engines.

V6 and V8 engines are more likely to have a hydraulic tensioner, as loads are generally higher and belts are longer. A hydraulic piston here moves a swing arm and roller assembly to change the tension. Hydraulic systems are usually low-maintenance, and any issues will most often mean just changing out the piston.

Common Drive Belt Issues

Since belts are tasked with turning the alternator (the car part that powers all electrics with the engine on), the water pump, the power steering and the air conditioning, any belt or tensioner failures can lead to very expensive repair bills. A failed alternator also means a depleted battery, difficulty starting, frequent stalling, dimming lights and more. A defective water pump often leads to engine overheating and damaged cooling system parts, while loss of power steering is a safety risk in itself.

While most belt and tensioner issues come on gradually, they should be addressed on time. Here are the common signs that point to either a frayed or worn belt or a tensioner assembly that’s stuck:

- Squeaking or grinding noises – These can happen when starting the car (and engaging the alternator) and when turning, signalling issues with the power steering pump.

- Accessory part failure – A faulty tensioner or belt can lead to problems with the parts and systems the belt drives, including air compressors, alternators and pumps.

- Belt wear and failure – This is one reason why belts malfunction prematurely (with fraying, wear and cracks the usual signs) is down to a failing tensioner assembly.

Causes and Troubleshooting

There are several causes. Different parts in the drive belt tensioner assembly can fail. Swing arms, brackets and the tensioner base are known to collect rust and this is evident only after the assembly have been removed.

Related are worn bearings, surface damage such as cracks and dents, collected debris, and chipping in the pulley sidewalls. If you see one or more of these in the accessory belt tensioner assembly, time for a new unit.

There can additionally be issues with the springs, the swing arms and how the parts are aligned. Worn springs mean loss of tension and slippage and the noises that come with it. Misaligned or stuck swing arms and the belt ‘jumping’ is down to worn arm bushings, or the parts that allow the arms and pulleys to move back and forth and tighten or loosen the belt as needed. And lastly, there can be excess play in the arms, often from a faulty vibration dampener as well as decouplers in an overrunning alternator pulley.

While the easiest way out is to try and repair the defective part, most problems mentioned above are solved with new tensioner assemblies.

Choosing Replacements

Pulleys and tensioner assemblies are relatively cheap, compared to the cost of any resulting repair work when they’re not functioning properly. The same applies for belts. While most units can last up to 100 thousand miles with regular service intervals and good maintenance, some variants can fail early on. Replacements are easy to find, and often from the same brand that makes the drive belt. Most mechanics will recommended changing both the tensioner and belt at the same time.

When replacing a damaged or worn drive belt tensioner assembly, consider vehicle compatibility and that you’re getting the right type for the model, trim and production year. Most drivers stick to OEM replacements and of the same type, but there is the choice to replace older manually-adjusted tensioner systems with automatic types. For peace of mind, and that you’re getting your money’s worth, look for rated warranty periods.

Summing Up

Belt tensioner assemblies are an essential part of vehicles with an internal combustion engine. Their task is to drive the various vehicle accessories while keeping belts taut, aligned and in good condition. Units struggling to deliver power to systems like the alternator or air conditioning should be replaced promptly before other damage occurs. Look for replacement tensioner assemblies at your local parts dealer and talk to your mechanic to get them installed.